Latest great work achieved by KU Leuven and Tecnalia: a flowsheet developed on how to obtain platinum nitrate with a purity higher than 99%. Watch the video below of the process and enjoy the precipitation process prepared especially for our subscribers!

KU Leuven and Tecnalia have created a flowsheet showing the complete nitrate manufacturing process: a total of 6 steps have been developed to obtain a platinum nitrate with a purity higher than 99%. KU Leuven developed and Tecnalia co-developed and carried out all the experimental work at large scale. Platinum nitrate is obtained from Batch A Pt-stripping in several stages, including cementation, leaching, precipitation and pH adjustment.

KU Leuven and Tecnalia have created a flowsheet showing the complete nitrate manufacturing process: a total of 6 steps have been developed to obtain a platinum nitrate with a purity higher than 99%. KU Leuven developed and Tecnalia co-developed and carried out all the experimental work at large scale. Platinum nitrate is obtained from Batch A Pt-stripping in several stages, including cementation, leaching, precipitation and pH adjustment.

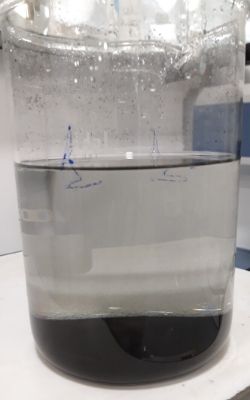

RESULTS: The product analysis showed a platinum concentration of 65% – the film of the precipitation process is shown below. The platinum extraction yield is 80% for the whole process, some is lost in the cementation stage and the rest washes, second filtrate and residue.

For the first filtrate, obtained in the Chloroplatinic acid treatment, there is platinum but this filtrate is recirculated to the process in the next cycle so it can be further recovered.

Finally, H2Pt(OH)6 is dissolved in concentrated HNO3 to obtain a w/w 15% platinum nitrate solution.